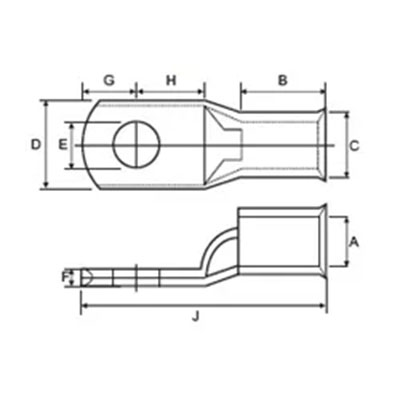

ALS Type Bimetallic Lugs

| SIZE mm2 | E BOLT MM ø | øA | øC | D | F | B | K | G+H | J | SONA’S Cat No. |

| 10 | M6M8 | 4.4 | 7.4 | 10.012.5 | 2.81.8 | 9 | 4 | 17 | 30 | SBL-1SBL-2 |

| 16 | M6M8 | 5.4 | 8.3 | 11.011.0 | 29.2.9 | 13 | 4 | 20 | 37 | SBL-3SBL-4 |

| 25 | M8M10 | 7.0 | 10.0 | 14.020.0 | 3.01.7 | 16 | 7 | 21 | 44 | SBL-5SBL-6 |

| 35 | M8M10 | 8.0 | 10.8 | 15.020.0 | 2.82.1 | 18 | 7 | 22 | 47 | SBL-7SBL-8 |

| 50 | M8M10 | 9.3 | 13.0 | 18.023.0 | 3.72.8 | 22 | 8 | 24 | 54 | SBL-9SBL-10 |

| 70 | M10M12 | 11.6 | 16.0 | 22.0 | 4.4 | 26 | 8 | 26 | 60 | SBL-11SBL-12 |

| 95 | M10M12 | 12.9 | 17.1 | 25.0 | 4.2 | 28 | 8 | 28 | 64 | SBL-13SBL-14 |

| 12 | M10M12 | 14.8 | 19.6 | 28.0 | 4.8 | 32 | 11 | 30 | 73 | SBL-15SBL-16 |

| 150 | M12M16 | 16.1 | 21.2 | 31.0 | 5.1 | 34 | 11 | 34 | 79 | SBL-17SBL-18 |

| 185 | M12M16 | 18.0 | 23.7 | 34.0 | 5.7 | 36 | 12 | 36 | 84 | SBL-19SBL-20 |

| 225 | M12 | 20.6 | 27.3 | 39.0 | 6.4 | 40 | 14 | 40 | 94 | SBL-21 |

| 240 | M12M16 | 22.0 | 28.0 | 40.0 | 6.0 | 44 | 14 | 44 | 102 | SBL-22SBL-23 |

| 300 | M16M20 | 24.0 | 31.0 | 45.7 | 7.0 | 47 | 14 | 47 | 115 | SBL-24SBL-25 |

| 400 | M20 | 28.0 | 36.0 | 51.0 | 8.0 | 56 | 13 | 56 | 130 | SBL-26 |

| 500 | M20 | 30.0 | 41.0 | 58.0 | 11.0 | 60 | 15 | 60 | 140 | SBL-27 |

| 630 | M20 | 35.0 | 46.0 | 66.0 | 11.0 | 69 | 16 | 69 | 154 | SBL-28 |

| 800 | 39 | 51.0 | 73.0 | 12.0 | 77.0 | 25 | 78 | 180 | SBL-29 | |

| 1000 | 43.5 | 57.0 | 81.0 | 13.5 | 100.0 | 30 | 90 | 220 | SBL-30 |

Tolerance = ± 5%

Technical Feature

TECHNICAL FEATURES OF BIMETALLIC TERMINALS

Sona’s Compression type Bi-metallic tubular terminal ends are basically made out of electrolytic grade aluminium. These aluminium terminals are first plated with copper and the electro – tinned.

The Bi-metallic terminal end barrel is Should be filled with corrosion inhibiting compound . This corrosion inhibiting compound is a mixture of fine metallic zinc particles suspended in high temperature grease, which is conductive and acts as electrical bridge between conductor strands. This compound plays role in breaking the oxide film which can form quickly on the surface of aluminium when exposed to atmosphere.

These Bi-metallic terminals are mainly used to terminate on copper bus-bars. Whenever aluminium links terminated on to copper or copper based alloy terminals without suitable plating, results in the corrosion of the joints over a period leading to higher joint resistance. BIMETALIC terminals found reliable and suitable for such connections.